Wavebar Classroom Noise Lowered

The challenges

Poor classroom design was negatively impacting students and staff at Randwick Park Primary School in Manurewa, Auckland, New Zealand. Classrooms were demonstrating excessive noise levels from heavy rainfall as well as loud noise transmission between classrooms.

The noise problems were two-fold as the design shortfalls meant that noise was clearly audible between classrooms, to the point of providing major distractions to young students. These distractions made it hard for students to concentrate and subsequently very hard for teachers to teach. However, noise transmission between classrooms was not an issue on days when it was raining as it was completely masked by the constant drumming of raindrops falling on the classrooms untreated steel roofs.

For students and teachers to be heard and understood effectively, loud voices and sometimes shouting would need to be used in competition with neighbouring classroom noise, rain noise and the volume from the children themselves. These circumstances provided a far from ideal teaching and learning environment.

The solutions

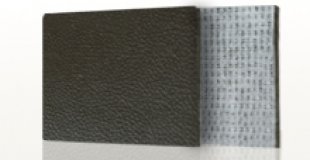

Pyrotek® New Zealand was consulted to specify a solution to reduce rain-noise and noise transmission between classrooms.Two soundproofing solutions were specified, both using Pyrotek's industry-leading flexible mass-loaded vinyl noise barrier Wavebar®. Wavebar® was specified for its outstanding acoustic properties, flexibility and durability.

Wavebar® was used to reduce transmission of sound between classrooms by creating a barrier between the ceiling and the roofing iron in the roof cavity. The ceiling in the classrooms consisted of a corrugated perforated panel and above the panels was a 50 mm thick glass-fibre blanket, with a commonly used roofing iron. Above the internal dividing wall between classrooms was an open pathway where noise could travel through the ceiling tiles via the cavity and down to neighbouring classrooms’ ceilings, plus reflecting from the underside of the roofing iron.

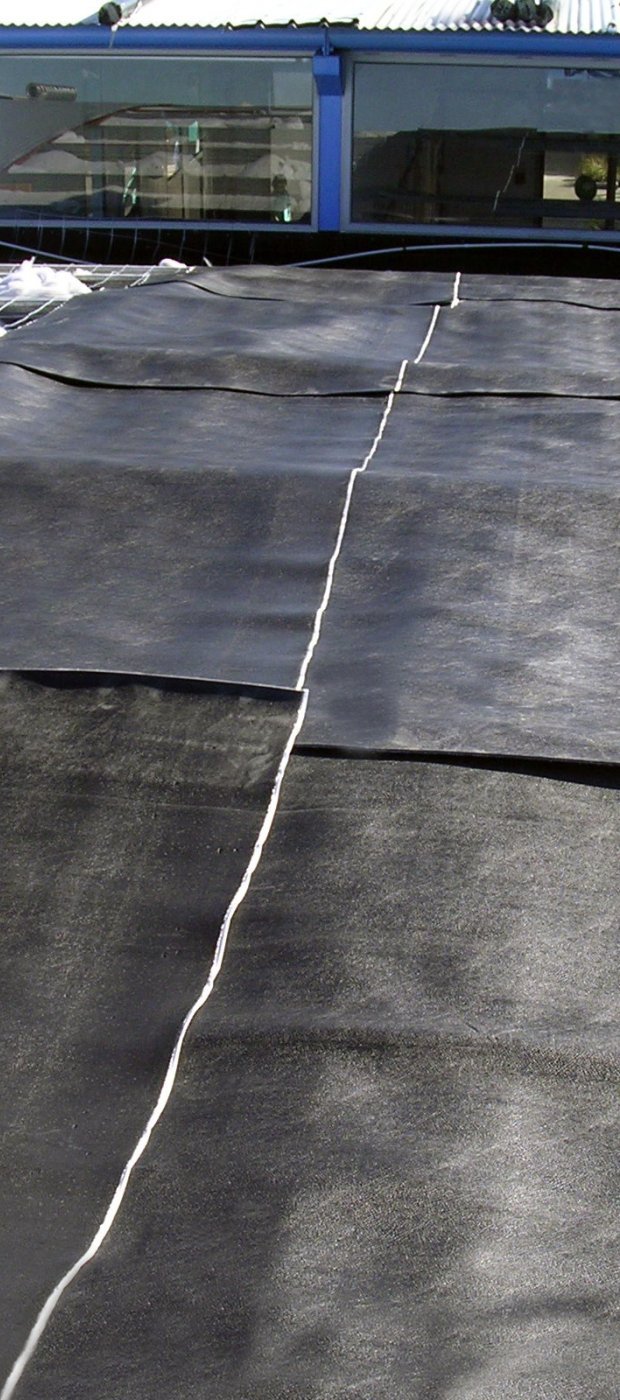

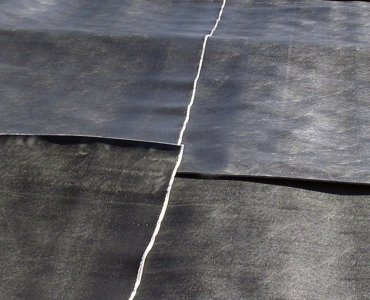

A double layer of 8 kg/m² Wavebar® was also installed directly above each dividing wall in the roof cavity, effectively blocking the transmission path of noise between the rooms. With a STC of 30 in a single layer, two layers of 8 kg/m² Wavebar® installed in this way provides further improved noise reduction. Note: A single layer achieves a CAC, (ceiling attenuation class) of 50 with standard ceiling tiles.Wavebar® was laid down as a “blanket” beneath the roofing iron and above the purlins, creating a complete barrier against noise transmission.

All of the Wavebar® in the ceiling cavity was fully sealed using a flexible mastic sealant to provide completely airtight seals between flashings, purlins and the roofing iron above – an important consideration.

Due to the weight of the product and size of the project, Pyrotek® supplied custom-cut rolls, so that the roll weight was more manageable and joints were supported by purlins. This also reduced labour and wastage during the installation. All joints were over-lapped at least 50 mm, thus creating a continuous acoustic barrier extending from the outer edges of the external walls across the entire roof area.

The results

After the installation, staff were very pleased with the results:

"Lovely and quiet. Now I can whisper when it rains and still be heard." Teacher – Classroom 10

"We noticed an immediate difference. It has provided a very peaceful atmosphere. It is not until you step outside that you realise it is actually raining. After an overexcited afternoon, I went to apologise to the teacher next door for disturbing his lessons – he replied, ‘I didn’t even notice it was noisy at all’." Teacher – Classroom 11