Thermal insulation reduces downtime, Quicker to maintain

The challenges

Typically in a processing environment, every second counts. Maintenance is a challenge in terms of inspection, easy removal of old insulation and replacement to keep insulation working in peak form. Many cases around the world demonstrate that it can be a lower priority however many don't know that paying attention to a simple (however time consuming) upgrade to insulation can create longevity and easy to maintain solutions. with the bonus of energy efficiency.

The solutions

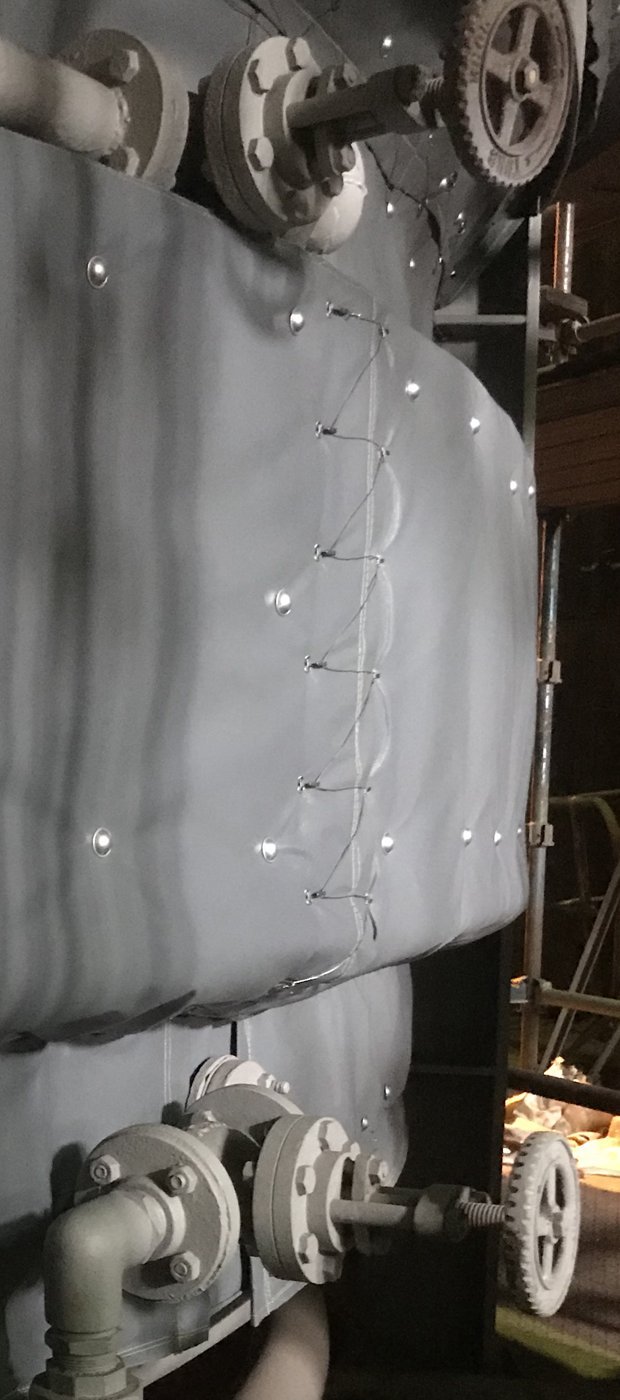

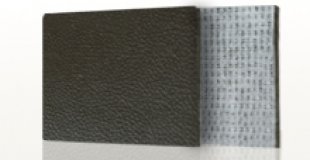

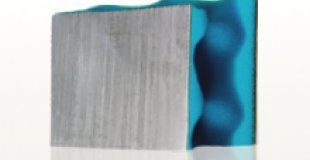

One factor that Pyrotek take into account is ease of maintenance and long term consideration of the use and reuse of insulation in these circumstances. Correct measure and quick production of customised jackets with any number of unique combinations of smart materials means the decision to upgrade insulation is simple. The perception and time savings are easy to see when gains of 70% time savings and less man power is required to simply undo the covers, and then put them back on.

The results

Often, the results speak for themselves. Safer, cleaner work areas and easier to identify and maintain machinery through better access, ease of cleaning (better surfaces able to withstand oil, grease and other spills). Effective, long lasting Insulation for pipework and ducting and processing chutes means better energy and thermal loss reduction, better noise control and safer industrial areas. The main benefit? Less maintenance downtime compared to conventional insulation and cladding that needs to be removed and reinstalled as new for when machinery requires attention.