acoustic pipe and duct lagging

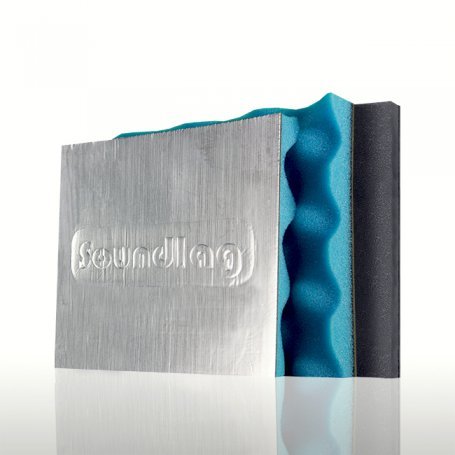

Soundlag® is a versatile high-performance composite acoustic lagging product, designed to effectively reduce noise from a variety of sources including pipes, valves, fan housings, and ductwork in commercial, industrial, and domestic buildings.

Soundlag® is the ultimate soundproofing solution for those seeking compliance with NCC (National Construction Code - formally Building Code of Australia) F5.6 requirements. With test results showing a significantly higher performance of up to 5 dB(A) compared to low-noise pipe products, Soundlag® is the clear choice for noise reduction.

The highly dense and flexible mass layer provides excellent sound reduction properties, whilst the decoupling layer breaks the vibration path between the substrate and the barrier, allowing the vinyl external wrap to remain flexible – optimising performance. The external foil facing offers a fire-resistant covering and an excellent surface to join adjacent sheets.

Pyrotek® offers varying compositions with barrier weights from 3 kg/m² to 8 kg/m² and the decoupling layer with a choice of plain or convoluted foam, polyester, fibreglass, glass wool or quilted glass wool with thicknesses ranging from 6 mm to 50 mm.

Black and white foil are alternative colour options to the reinforced aluminium facing. These anti-glare foil colours are suitable for exposed ceiling spaces.