Burj Khalifa luxury high rise building in Dubai

The challenges

Completed in 2010 this global icon Burj Khalifa includes 900 private, ultra luxury residences and corporate suites.

Apartment owners globally need consideration to acoustics in their homes - even when conforming to building codes and standards - providing a comfortable level of quietness in high density residential buildings can be challenging for builders.

In high rise, multi-story buildings the plumbing runs near the ceiling of the room below so soundproofing to some degree is essential. Hydraulic engineering provides proper consideration for pipelines in terms of location and the need to optimise space. The Burj Khalifa building received many MEP (mechanical, electrical and plumbing) awards for engineering.

The Burj Khalifa’s vast water system supplies an average of 946,000 L (250,000 U.S. gal) of water per day through 100 km (62 mi) of pipes. An additional 213 km (132 mi) of piping serves the fire emergency system, and 34 km (21 mi) supplies chilled water for the air conditioning system. The immense scale of this building meant a huge requirement of pipe lagging.

The solutions

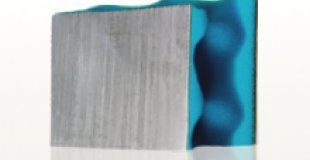

With the scale and calibre of this development, prior experience and a proven solution for pipe lagging was required. Credible test results backed up supply and the order was filled. The ultra luxury residences in the tallest building in the world enjoy the silence of soundproofing from waste water pipes. Lagged to protect residents from neighbouring waste water noise, the pipework was a complex task with levels and many varied configurations of subfloor utilities, systems of hydraulic facilities.

The external foil facing offers a fire resistant covering and an excellent surface to join adjacent sheets.

Pyrotek’s flexible mass-loaded vinyl (MLV) noise barriers offer superior acoustic transmission loss. With adequate performance and compliance to acoustic requirements for pipe lagging it contains no ozone depleting substances,

The results

Approved by several International Association of Classification Society (IACS) companies for waste water systems, Soundlag is one of the easiest & quickest products on the market to install. Tape ALR is simple to tear and apply to create noise-proof joins and quickly lag pipes even across complex or tight areas.

With a long history in similar applications, Soundlag was approved to install with suitable barrier weight for the purpose, and chosen to last for the entire life of a building. Typical noise from bare wastewater pipes can be measured as Sound Power Level (SWL) of 67 dB(A). When lagged with Soundlag, the SWL drops to 23dB(A) – almost inaudible, the experience of living near to pipes instantly becomes less of an imposition. Various compositions of systems can be known achieve reductions/insertion loss by upto 29 dB.

*Tested at National Acoustic Laboratories,Report Number: ATF750B, ATF750C & ATF750D