Engineered to Last - Acoustic Solution for Water Management

The challenges

Water is an essential part of our lives and its management not only is but must be part of today’s world in order to prevent serious damaging effects it can have if left uncontrolled. However, high levels of noise come hand in hand with the machinery used, if left untreated. Noise control plays a crucial part in water management - whether its goal is to secure a safe and productive worksite or to save lives by providing flood relief and emergency service plumbing.

Pyrotek has for a number of years played an important part not only in securing these healthier work environments but also in protecting surrounding areas of such worksites from the inevitable noise of heavy machinery. Whether it is removal of surface and ground water prior to any construction work or water control in mines in order to secure a safe and productive work environment for the crew, Pyrotek solutions are the go-to products to mitigate noise and vibrations from the heavy machinery needed for these processes and to ensure quiet operation. Our premium acoustic products allow for reduced downtime and increased productivity for the end user, but at the same time, they protect human health.

Pyrotek’s extensive expertise in noise mitigating material design is what led to our team being entrusted with the development and manufacture of custom-designed acoustic solutions for a global leader in dewatering pumps fabrication. With 50 years of experience in the industry, the manufacturer knew the importance of integrating acoustic solutions in the design of their water management equipment. Mitigating the high levels of noise such pumps generate is a must in order to protect the work crew and residents alike when used in urban areas, especially since when in operation, the pumps are often running constantly.

The solutions

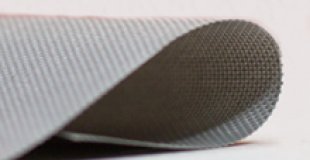

Given the type of application and environments dewatering pumps are used in, outdoor use and a high potential of water contamination and leakage into the system were factors increasing the challenge. Standard foams commonly used to absorb noise, such as polyurethane foams, were out of the question due to their ease of absorbing water. Moisture trapped inside will result in degraded performance with effects commonly associated with water exposure: mold, mildew, rotting and bacteria. Additionally, wet materials filled with water will not deflect heat or air, making them ineffective thermal insulators. The goal was therefore to design a solution that would not only offer premium acoustic absorption but also one that would be easy to install and sustain constant use in such a challenging, harsh environment.

Our experienced team knew it was important to treat the issue directly at its source – the pump itself. Pyrotek’s R&D specialists and Engineering Department worked diligently together to design and offer a solution for multiple new models of dewatering pumps. Custom-made Sorberpoly™ 2D GC interior lining kits for the pump enclosures were developed. Sorberpoly 2D is a premium non-woven polyester with excellent sound absorbing and thermal insulation properties. Being hydrophobic (non-wicking), it is especially well suited for high humidity applications. A black glass cloth facing (GC) was thermally bonded to Sorberpoly 2D using a unique method, resulting not only in maximum durability and acoustic performance, but improved fire ratings as well.

The purpose of such design - a non-woven polyester noise absorber with a glass gloth facing - was not only to reduce the noise impact on the surrounding environment, but to also create an acoustic product suitable for harsh conditions where high temperature and abrasion are an issue. Further protection from mechanical damage and dirt ingress was needed and this is where the glass cloth facing provides maximum durability on top of premium acoustic performance. Additional benefits include minimal weight, no-hassle install and safety. Being an extremely lightweight material, the use of Sorberpoly 2D™ GC for the enclosure lining did not affect the ease of manipulation or mobility of the pump as very little extra weight was added. The product is also easy to cut using scissors or a sharp knife and is safer than fibreglass or rockwool alternatives.

The results

The Pyrotek solution provided a much needed added value to the manufacturer’s dewatering pumps, making them quieter than major competition. The manufacturer was thrilled with our team’s acoustic solution as the noise levels were brought down to 65 dB(A) at a distance of seven metres, offering quieter working conditions and protection from high noise levels to urban areas. These pumps are now being manufactured with acoustic canopies internally lined with water-resistant and fire-retardant Pyrotek® custom kits made from Sorberpoly 2D GC, a durable acoustic absorber allowing for extended service life even in the most challenging applications. A product that provides not only healthier conditions for the workers but also has minimal noise impact to the local environment.