Industrial Chiller Pipe lagging quietens Office

The challenges

Manufacturing equipment generates heat and thus large, industrial air-cooling units are used to cool areas where required. Process cooling equipment designed to work in manufacturing areas can have many different forms and volume levels and for one large world-renowned oil company in Singapore, a noise challenge became evident near equipment and pipework used to cool the office area. Whilst this equipment was external, it created unacceptable noise levels for staff due to it's close proximity.

To safely improve the acoustics between the noise source and office spaces, the solution would also need to comply with strict local fire and toxicity regulations, and provide an easy, low maintenance installation method.

The solutions

NAP Acoustics, a specialist acoustic firm with a global presence were familiar to the many effective solutions Pyrotek has to offer and so were confident in recommending Soundlag and Wavebar for the noise treatment.

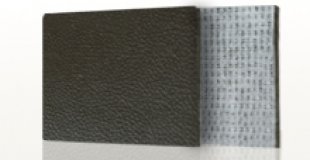

Soundlag is composite acoustic lagging comprised of a highly dense and flexible foil-faced mass loaded vinyl layer and decoupling acoustic foam. Soundlag is a tested and proven product, installed successfully into many projects globally and offering compliance to a plethora of international acoustic and fire standards. When used to wrap the chiller pipework Soundlag created an effective acoustic seal even across various pipe configurations. Its complementary properties facilitate the need to meet the required fire regulations, - it provided additional benefits: improving thermal insulation and providing a reduction of condensation formation on pipes, potentially resulting in CUI (corrosion under insulation).

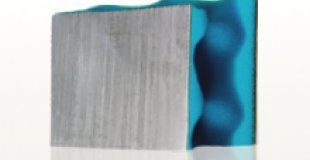

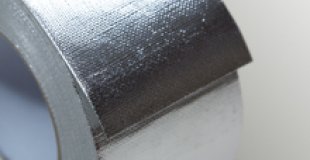

Wavebar, is a highly flexible, thin-layered mass loaded vinyl noise barrier. Wavebar was used to seal gaps around pipe penetrations further improving the effectiveness of the complete solution. All products, for a quick and easy install, were joined using Pyrotek’s AGC Tape.

The results

The cooling system is now insulated and acoustic engineers from Nap Acoustics measured an approximate drop of 10dB within office spaces and in the immediate surrounding areas of the chiller unit resulting in a cool, quiet and ultimately comfortable working environment. Thankfully, due to good installation on the pipe chiller, a good seal was established and this resulted in a suitable noise reduction for the area, leaving staff exceptionally impressed with the performance of the products. The Pyrotek solution was easy to install and will last for the life of the equipment with the added bonus of improved fire resistance.

With an effective insulation solution, the owner is able to maintain level system costs and ensure a safer, quieter operation for staff.