Pyrotek Keeps Mining Giants Quiet

The challenges

Underground mining operations use some of the largest and most powerful earth moving equipment on the planet. Both the engines that drive this machinery, and the machine contacting on hard rock, generate significant noise and vibration. And there is little opportunity for noise to escape in an underground mine. Workers operating this equipment need to be protected from excessive levels of noise. This is not just for their comfort; it is about protecting their long term health, as well as providing an environment that maintains productivity.

Machinery operators need be at their peak and make sound decisions when controlling many tonnes of machinery, and so a reasonably comfortable working environment is essential.

One of the challenges in making the cab was to isolate the operator from excessive noise.

The solutions

A research and development department of the world’s finest mining equipment, modified a CAT grader so that it would be suitable for underground mine use. The modifications included changes to the chassis, as well as fabricating a low profile cab to allow the grader to fit in areas with height restrictions.

Combining suitable products for maximum benefit, Pyrotek were invited to apply their specialised sound control expertise to this extreme environment. Five existing Pyrotek products were combined to control noise and vibration:

1. Decidamp® SP80, fast drying, water based, thixotropic vibration damping compound, was applied to the entire cab before painting. Soundpaint dampens vibration, reducing the ringing or tinniness from metal panels and structures.

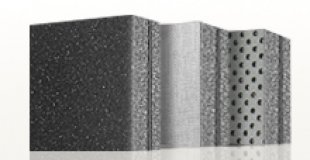

2. Sorberbarrier, unique composite noise control product, was applied to the interior cab roof. This foam substantially absorbs noise energy across the entire frequency range.

3. Sorberscreen, perforated metal screen with a flow resistant backing textile, was custom cut and fitted as the finished surface ceiling panel. Sorberscreen provides high performance sound absorption and is the product of choice in engine rooms and the like.

4. Sorberbarrier with PSA was fitted to the lower cab walls with pressure sensitive adhesive, further absorbing noise energy.

5. Silentstep, flexible mass-loaded barrier, was custom cut and fitted to all floor surfaces. Floor mats reflect and absorb sound vibration, reducing noise transmission.

The results

The team are very pleased with the outcome and the noise reduction that has been achieved. They are confident the modified grader will prove popular with mining companies and machine operators.